It started on a quiet weekend with a stubborn 2x4, a borrowed circular saw, and way too much confidence. One uneven cut later, I realized this tool deserved far more respect—and maybe a sturdier pair of shoes. Since then, I’ve tested, tinkered, and even made a few near-perfect cuts chasing the best circular saws on the market. These machines are more than just power tools—they’re problem-solvers, time-savers, and (when used right) oddly satisfying to master. In this story, I’ll share what really separates a good circular saw from a great one, what specs actually matter, and how a bit of sawdust can lead to some surprisingly sharp insights.

Getting to Know Circular Saws: Myths, Marvels, and Monday Mistakes

Let me start with the basics: a circular saw is simply a handheld power tool with a spinning blade that cuts through materials. Think of it as the Swiss Army knife of cutting tools – portable, versatile, and surprisingly user-friendly once you get past the initial intimidation factor.

Three Stories That Changed My Mind About Circular Saw Uses

My first encounter with a circular saw was a disaster. I was 22, trying to build a bookshelf, and ended up with wonky cuts that looked like abstract art. Fast-forward five years: I watched my neighbor Sarah, a complete beginner, make perfect straight cuts on her first try with a modern circular saw. The difference? Better safety features and proper guidance.

Then there's Mike's Monday morning mistake – he grabbed the wrong blade and tried cutting metal decking with a wood blade. The result? Sparks, frustration, and a valuable lesson about circular sawapplications requiring the right blade for each material.

'When I hand a beginner a circular saw, their confidence jumps ten notches after the first straight cut.' — Louisa Ramos, Master Carpenter

Why Circular Saws Stand Out: The Triple Threat

Portability is the first marvel. Unlike table saws that anchor you to one spot, circular saws travel anywhere your project needs cutting. I've used mine on rooftops, in basements, and even outdoor job sites.

Versatility comes second. With proper blades, these tools cut wood, metal, masonry, plywood, and yes – even concrete. The circular saw benefits extend far beyond basic lumber work.

Cost-effectiveness seals the deal. Entry-level models start around $50, while professional-grade versions rarely exceed $200. Compare that to a quality table saw, and the value becomes crystal clear.

Busting Common Myths About Circular Saw for Beginners

Myth 1: They're too dangerous for novices. Modern circular saws include blade guards, electric brakes, and ergonomic designs that prioritize safety.

Myth 2: They're complex to operate. Most circular saws have just two controls: the trigger and depth adjustment. That's simpler than many kitchen appliances.

Myth 3: They're limited in capability. Wrong. Professional contractors rely on circular saws for everything from framing houses to cutting tile.

Material Possibilities: Beyond Wood

Here's where circular saws truly shine. Wood remains the most common application, but with specialized blades, you can tackle:

Metal pipes and sheets

Concrete and masonry blocks

Plastic and composite materials

Laminate flooring

Compared to other saw types, circular saws offer the best balance of power, precision, and portability for most DIY and professional applications.

Unpacking the Key Features: What Actually Matters (Not Just Brand Buzzwords)

After testing dozens of circular saws and making my fair share of wonky cuts, I've learned that fancy marketing terms often hide what really matters. Let me break down the circular sawfeatures that actually impact your work—not just your wallet.

Motor Power: The Heart of Every Cut

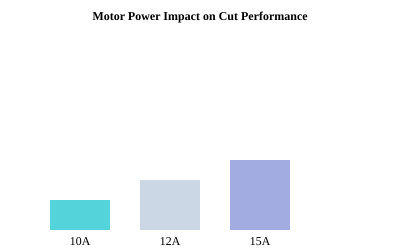

Motor amperage isn't just numbers on a label. I've used 10-amp, 12-amp, and 15-amp saws, and the difference is real. My 15-amp saw powers through 2x10 lumber like butter, while my old 10-amp model would bog down and burn blade edges. Circular sawpower and portability create an interesting trade-off: more amps mean cleaner cuts but heavier tools.

Blade Size and Cutting Depth Reality Check

Standard circular saw blades range from 6.5 to 7.25 inches. Here's what I've discovered: that extra quarter-inch in blade diameter translates to about half an inch more cutting depth. My 7.25-inch saw cuts through 2x8s in one pass, while my compact 6.5-inch model requires flipping the board.

Bevel Adjustments: From Wobbly to Wonderful

My first bevel cuts looked like a drunk carpenter's handiwork. The key isn't just having bevel adjustment—it's having precise bevel adjustment. Quality saws lock firmly at common angles like 45 degrees. Cheap models drift, creating those signature "almost-right" cuts.

Safety Features That Actually Work

The circular saw blade guard isn't optional equipment—it's life insurance. I've seen spring-loaded guards jam with sawdust and retractable guards stick. The best circular saw safety features include trigger locks that prevent accidental starts and guards that snap back instantly after cuts.

"More buttons don't get you a straighter cut; knowing your tool does." — Ivan Lee, Tool Test Editor

Corded vs. Cordless: Why I Own Both

Corded saws offer unlimited runtime and consistent power. Cordless models average 30-60 minutes per charge but provide unmatched mobility. I grab my cordless saw for quick deck repairs and my corded model for kitchen cabinet installations.

The Blade-Change Victory Story

Mid-project blade changes used to involve colorful language and skinned knuckles. Modern saws with tool-free blade changes transformed this task from nightmare to 30-second swap. Precise adjustments and blade swaps enable more types of cuts without switching tools.

Remember: fancy features that collect sawdust aren't worth the extra cost. Focus on motor power, blade quality, and safety—the fundamentals that make every cut count.

Circular Saw Pros and Cons: The Truth from My 2AM Garage Projects

Let me be honest about something. Most of my best circular saw discoveries happened at ridiculous hours when normal people are sleeping. There's something about a midnight woodworking session that reveals the true character of your tools. After countless late-night projects and a few "learning experiences" that left me questioning my life choices, I've got some real talk about circular saw pros and cons .

Why Beginners Love Circular Saws (Spoiler: Speed and Simplicity)

Here's why circular saws win over impatient DIYers like me: they're ridiculously fast. While my neighbor spends twenty minutes setting up his miter saw for one cut, I'm already making sawdust. The circular saw learning curve is surprisingly gentle – I had my first decent cuts within an hour of unboxing.

"Circular saws are like the Swiss Army knives of cutting tools." — Grace Turner, Renovation Coach

The Pros That Actually Matter

Circular saw cost effectiveness – Basic models start at $50, while pro-grade versions max out around $200

Circular saw portability – I've hauled mine on camping trips, squeezed it into my Honda Civic's trunk, and carried it up three flights of stairs

Setup time under 5 minutes for most cuts

Versatility across materials – lumber, plywood, even light metal with the right blade

The Not-So-Perfect Reality Check

Let's talk about where circular saws struggle. That 4x4 beam I tried cutting at 2 AM? Yeah, that was optimistic. Thick materials bog down smaller saws, and the dust storms they create are legendary. I learned to wear safety glasses the hard way – nothing says "amateur hour" like squinting through sawdust clouds.

Limited precision for repeated cuts without guides

Struggles with thick beams (over 2 inches gets challenging)

Dust management requires extra planning

Blade changes can be fiddly in poor lighting

Portability Pros: Real Travel Stories

Last summer, I drove 300 miles to help my sister with deck repairs. My circular saw, two blades, and a small toolbox fit perfectly in my car's trunk alongside vacation gear. Try doing that with a table saw. The circular saw portability factor makes it ideal for job site work and home projects alike.

Budget vs. Durability: Where Not to Skimp

That $35 saw I bought for "light use"? It lasted exactly three plywood sheets. Investing in the $80-120 range gets you motors that won't burn out during ambitious projects. The sweet spot balances circular saw cost effectiveness with reliability that survives those inevitable 2 AM inspiration strikes.

Where Circular Saws Shine: Best Uses and Who *Shouldn't* Buy One

I've learned that circular saws are the Swiss Army knives of the power tool world. As Joe Kenney from Pro Remodeler puts it: "If you own just one saw, make it a circular." But like any tool, they have their sweet spots and their limitations.

Circular Saw Applications: Where They Excel

Let me share where these workhorses truly shine. For framing work , nothing beats a circular saw's speed and portability. I've watched framers zip through 2x4s like butter, creating entire wall sections in minutes. The circular saw project versatility extends to:

Building basic furniture (bookshelves, workbenches, storage units)

Cutting plywood sheets for subfloors or cabinet backs

Quick demolition work when renovating

Trimming deck boards and siding

Basic cabinetry construction

I once used my circular saw to rescue a garden door that had swollen shut after heavy rain. Three quick cuts through the binding edge, and the door swung freely again – a job that would've taken forever with a handsaw.

Circular Saw Cutting Materials: What They Handle

The circular saw benefits and uses extend across materials. With the right blade, mine cuts through wood, plywood, MDF, and even thin metal. I've sliced everything from pressure-treated lumber to laminate flooring without missing a beat.

When Circular Saws Fall Short

However, circular saws aren't brilliant for everything. They struggle with:

Delicate joinery work requiring precision cuts

Scroll cuts or intricate curves

Identical repeat cuts (that's table saw territory)

Ultra-fine finishing work

Remember, these tools excel at renovation and repair projects but aren't fine-joinery instruments.

Who Gets Maximum Value

Circular saws deliver exceptional value for:

Homeowners tackling weekend projects

Renters needing portable cutting power

Remodelers working across multiple sites

Occasional builders who need versatility over specialization

Who Should Look Elsewhere

If you're primarily doing precision woodworking, consider these alternatives:

Miter saws for accurate crosscuts

Table saws for repetitive rip cuts

Handsaws for delicate detail work

Professional cabinet makers and fine furniture builders often need these specialized tools for their exacting standards. But for most DIY enthusiasts and general contractors, a quality circular saw handles 80% of cutting tasks with remarkable efficiency.

How to Choose the Right Circular Saw: Beyond the Shiny Packaging

I learned this lesson the hard way when I bought my first circular saw. The box was gorgeous, the marketing promised professional results, and the price seemed reasonable at $65. What they didn't mention was that the motor would struggle through a 2x4 and the blade guard would stick after six months of weekend projects.

Start With Your Projects, Not Your Ego

Before diving into any circular saw buying guide , honestly assess your typical work. Are you building a deck, trimming door frames, or just making occasional cuts? For basic home projects, budget picks in the $50-$70 range work perfectly fine. I wish someone had told me this before I initially overspent on features I never used.

The Blade Mix-Up That Cost Me $40

Here's my embarrassing story: I once tried cutting aluminum siding with a wood blade because "it looked sharp enough." The result? A destroyed blade, rough cuts, and a trip to buy the correct metal-cutting blade. Circular saw blades matter more than the saw itself sometimes. Wood blades have fewer, larger teeth. Metal blades have fine teeth. Masonry blades are completely different. Match the blade to your material, always.

'Choose the blade for the job, not the brand for your ego.' — Danica French, Home DIY Blogger

Power vs. Portability Reality Check

Heavy-duty doesn't always mean better. My 15-amp corded saw cuts beautifully but weighs nearly 12 pounds. For overhead work or long sessions, that weight becomes brutal. Consider your physical comfort alongside power needs. Sometimes a lighter 12-amp model is the smarter choice.

What Actually Breaks First

In my experience, the circular saw blade guard mechanism fails before the motor does. Cheap plastic guards stick or break within a year. Look for spring-loaded, metal-reinforced guards. The average blade lasts 35-50 hours depending on material, but a broken guard makes any saw dangerous.

Essential Buying Checklist

Motor: 12-15 amps for most tasks

Blade size: 7-1/4" is standard for versatility

Base plate: Aluminum beats plastic

Hand feel: Actually hold it in the store

Warranty: Minimum 2 years for peace of mind

For circular saw price comparison , expect budget options around $50-$70, mid-tier quality at $85-$130, and professional grade starting at $150+.

Finding Honest Reviews

Skip the top Google results filled with affiliate links. Check YouTube for actual usage videos, visit local hardware stores for hands-on advice, and read reviews from people who've owned their saws for over a year. Real-world circular saw recommendations come from people who've actually used them through multiple projects.

Maintenance, Safety, and the Secret Life of a Well-Loved Saw

I learned about circular saw maintenance the hard way when my favorite saw started making grinding noises during a deck project. That grinding sound? It was my blade crying for help, and I nearly ruined both the project and the tool by ignoring basic maintenance.

Quick-Clean Hacks You Can't Forget

After every five uses (or monthly if you're casual), I do my unglamorous routine that's worth every minute. First, I blow out sawdust from the motor housing using compressed air. Then I wipe down the base plate with a damp cloth—resin buildup here affects cut accuracy more than you'd think.

For blade cleaning, I use oven cleaner on stubborn pitch. Spray it on, let it sit for ten minutes, then scrub with an old toothbrush. This simple step extends blade life significantly and keeps cuts smooth.

My Near-Disaster Blade Swap Story

During a kitchen cabinet project, I ignored my dull blade's warning signs—rough cuts, burning smell, increased kickback. When I finally swapped it, I discovered the blade bolts were loose too. That combination nearly caused serious kickback that could have injured me. Now I check blade tightness every few projects and replace blades when they're dull or chipped, not when they're destroyed.

Circular Saw Safety Tips the Manual Skips

'Half of saw safety is just not rushing the job.' — Eliza Grant, Workshop Teacher

Beyond basic circular saw safety features like blade guards, I've learned these overlooked safety habits:

Always check your cord for nicks before plugging in

Test the safety guard's spring-return action monthly

Keep both hands on the saw during cuts—never use one hand to hold material

Let the blade come to complete stop before setting down the saw

Storage and Transport Protection

A good case makes all the difference. After watching a friend's saw get damaged in his truck bed, I invested in a hard case. It protects the base plate from scratches and keeps the blade covered during transport.

For storage, I hang my saw on a pegboard hook, keeping the cord wrapped loosely. Tight cord wrapping creates internal wire damage over time.

My Regular Check Routine

Every few projects, I inspect these circular saw maintenance tips essentials:

Blade bolts for tightness

Battery connections (for cordless models)

Power cord for damage

Safety guard operation

Base plate alignment

This routine takes five minutes but prevents costly repairs and dangerous failures. Simple maintenance like this extends tool life, reduces risk, and ensures happy DIY outcomes every time.

The Final Cut: Verdict, Recommendations, and 'If I Could Only Have One…'

After years of sawdust in my hair and countless projects, here are my real-world circular saw recommendations based on who you are, not just what looks good on paper.

Best Circular Saws by User Type

For Beginners: Start with a lightweight saw under $100. I wish I'd known this when I bought my first saw—I went overboard with a 15-amp beast that left my arms screaming after 30 minutes. A 12-amp corded saw or decent cordless model will handle 90% of beginner projects. Check latest price here on entry-level models that won't break your budget or your back.

For Weekend Warriors: The all-arounder with a 13-15 amp motor hits the sweet spot. It's powerful enough for deck building but won't intimidate you during simple cuts. These typically run $80-$150 and represent the best value in circular saw reviews . Check latest price here for mid-range options.

For Professionals: Motor power above 15 amps, price range $150-$200. These saws mean business. After destroying three cheaper saws on a bathroom renovation (my biggest failure story), I learned that pros need tools that can handle 8-hour days without complaint. Check latest price here for professional-grade models.

My Wildest Success Story

I once built an entire treehouse with just a circular saw and basic hand tools. The secret? Measuring twice, cutting once, and having the right blade for each material. That project taught me more about circular saw recommendations than any manual ever could.

"A circular saw can turn any hunk of lumber into a project with potential. The rest is up to you." — Sam Patel, Furniture Builder

SAWpocalypse Scenario

Imagine being trapped in a hardware store with only a circular saw. Beyond cutting lumber, I've used mine to:

Create kindling for emergency fires

Fashion makeshift shelter supports

Cut PVC pipes for water collection

Trim metal sheeting (with proper blade)

If I Could Only Have One

Honestly? A corded 15-amp saw with a good dust port and solid base plate. It's not sexy, but it's reliable. Cordless is tempting, but when push comes to shove, I want guaranteed power. The best circular saws aren't always the flashiest—they're the ones still running when others quit.

Remember: there's no universal "best." Find your fit based on your actual projects, comfort level, and the features that matter to your workflow.

Quick Answer Corner: FAQs from the Sawdust-Covered Crowd

After spending countless hours in workshops and reading through forum threads, I've noticed the same questions pop up again and again. Let me tackle the big five that keep beginners up at night.

Is a circular saw safe for first-timers?

Absolutely! I won't sugarcoat it - any power tool demands respect. But with proper circular saw safety tips , beginners actually find these tools less intimidating after their first use. Start with these basics: always wear safety glasses, keep both hands away from the blade path, and let the blade stop completely before setting the saw down. The guard system on modern saws provides excellent protection when you follow basic rules.

What's the best blade for plywood?

This is where circular saw blades make all the difference. For plywood, I recommend a fine-tooth blade with 60-80 teeth. The more teeth, the smoother your cut. A standard 24-tooth framing blade will tear up your expensive plywood faster than you can say "oops." Trust me on this one - blade selection determines cut quality more than the saw itself.

Do cordless models have enough power?

Modern cordless saws pack surprising punch. Today's 18V and 20V models handle most DIY tasks without breaking a sweat. Expect 30-60 minutes of typical runtime, which covers most weekend projects. I've cut through 2x4s, plywood, and even pressure-treated lumber with my cordless saw. The convenience often outweighs the slight power difference from corded models.

"No tool made me feel like a real DIYer faster than a circular saw." — Monica Liu, Renovation Enthusiast

How do I stop my cuts from splintering?

Splintering drives everyone crazy, but the fix is simple. Score your cut line lightly with a utility knife first, or apply painter's tape along the cut. Also, make sure your blade is sharp - dull blades tear rather than cut cleanly. For the smoothest cuts, place the good side of your material face-down, since circular saws cut upward.

Can one saw handle wood and metal?

Yes, but you'll need different blades. Your standard wood blade will destroy itself on metal, and metal-cutting blades move too slowly for efficient wood cutting. I keep both types handy and swap them based on the project. Most circular saws for beginners come with basic wood blades, so budget for specialty blades as your projects expand.

These questions represent the real concerns I hear from workshop newcomers. Once you understand these fundamentals, your confidence will soar along with your project success rate.